A1: Yes, our factory is in Shenzhen, china. Specializing in rechargeable batteries. Lithium ion batteries, lithium batteries and power batteries and chargers for more than 10 years.

A2: All of our e-bike batteries come with charger.We have normal charger and fast charger.If you need fast charger please contactwith us

A3: Yes, Our batteries all with SEIKO IC BMS, with stable performance.Which can protect the battery avoid short circuit,Overcharged,Overdischarge and Overcurrent.

A4: Electric Bike Battery will be sent out within 5 days after confirmed order,shipping will cost 3-15days,it depend on quantity and which battery you need.

The battery should have around 800-1200 recharge cycles, about 2-3 years.Its capacity diminishes over time, when it goes down to 75%,you should replace it.The more you use the bike, the better the battery retains its capacity, since it keeps the Lithium moving.

The battery should be stored in clean, dry, ventilated, dark environment when not using.Keep it after full charge,recharge it every 3 months or 6 months.

Yes, We are a professional Electric Bike Battery manufacture with factory, which produce all kind of high quality Ebike lithium batteries as customers' requirements and designs, welcome to place OEM and ODM orders and visit our factory.

Ebike Li-ion battery have longer cycle life,normal cyclelife is 6000-8000times, and also with light weight, small size, No-memory effect, Nontoxic, environmental.

The price come with Bus bars and Bolts,One Battery will come with one set bus bar and bolt(e.g.,If buy 4pcs battery,we will send 4pcs cells with 4pcs busbars and 8pcs bolts)If need more please contact us online.

Pack with strong package, each cell into thickness PE foam or bag, then into 5 layers strong carton.

Key attributes/Other attributes

Battery Type LiFePO4

Brand Name Easternproject

Weight about 140KG

Type Split

Communication Port RS232, RS48

Protection Class IP65

Grid connection Off grid, Hybrid grid

Product name Home Powerwall Batter

Voltage 48V/51.2V

Nominal Capacity 280AH/300AH/330AH

Warranty 5years

Certification CE/RoHS/UN38.3/MSDS

Cycle life 6000 Times

OEM/ODM Customized OEM ODM Battery Pack

Cell type GradeA Lithium-ion

Communication CAN/RS485/DRY CONTACT

ApplicationElectric Power Systems

Packaging and delivery

Packaging Details

House electricity storage off-grid power Solar battery for solar energy system

wooden case packing for generator ,controller used carton box packing .inverter used carton or wooden box packing .

Customerized 48V LiFePO4 battery pack

Product Features:

1.Electrode space protection board: Advanced electrode space protection board technology is adopted to ensure the safety and stability of the battery under various working conditions. 2.Touch screen display: Equipped with a 4.3-inch high-definition touch screen display, it shows the battery status in real time, including voltage, current, battery percentage, etc. The operation is simple and intuitive.

2.Touch screen display: Equipped with a 4.3-inch high-definition touch screen display, it shows the battery status in real time, including voltage, current, battery percentage, etc. The operation is simple and intuitive. 3.Automatic fire extinguisher: It is equipped with an automatic fire extinguisher. Once an abnormal situation is detected, such as overheating or short circuit, it can quickly activate the fire extinguishing mechanism to ensure safe use.

3.Automatic fire extinguisher: It is equipped with an automatic fire extinguisher. Once an abnormal situation is detected, such as overheating or short circuit, it can quickly activate the fire extinguishing mechanism to ensure safe use.

4.Stacking design: Supports battery stacking, allowing for flexible expansion of battery capacity as needed. Up to 4 batteries can be stacked to meet the energy demands of various scenarios.

5.Convenient connection: It is designed with quick connection terminals for positive and negative poles, making battery connection more convenient and faster, and saving installation time.

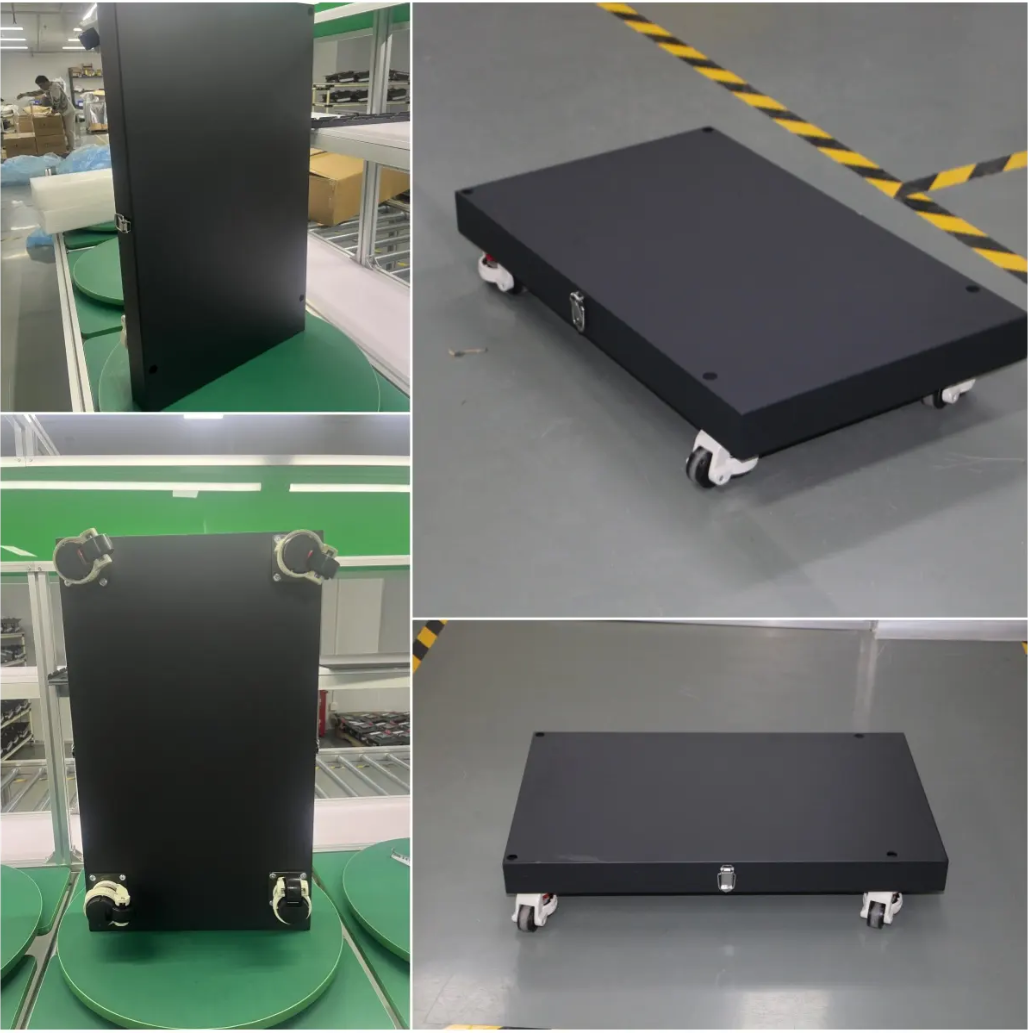

6.Reinforced 4-wheel base (optional) : An additional reinforced 4-wheel base can be purchased to enhance the mobility and stability of the battery system.

7.High-quality materials: Manufactured with high-quality materials, ensuring the battery's durability and long lifespan.

8.Safety performance: It is equipped with multiple safety protection mechanisms, including overcharge protection, over-discharge protection, short-circuit protection, etc., to ensure the safe use of the battery in various environments.

To create a customized 48V LiFePO4 battery pack, several factors need to be considered, including the desired capacity, configuration, dimensions, and intended application. Here's a general process for us to make such a battery pack:

Determine Requirements: Understand the specific requirements for the battery pack. This includes voltage (48V), capacity (measured in ampere-hours, Ah), discharge rate, size constraints, weight limitations, and any other relevant factors.

Select Cells: Choose the appropriate LiFePO4 cells for the battery pack. We choose the grade A and original branded new LiFePO4 battery, 16 pieces 3.2V 100ah, 200ah,300ah, Ensure they meet the required specifications and quality standards. Consider factors such as energy density, cycle life, safety features, and availability.

Calculate Configuration: Determine the configuration of the battery pack, including the number of cells and their arrangement (series and parallel connections). This calculation will depend on the desired voltage (48V) and capacity requirements.

Design Enclosure: Design or select an enclosure for the battery pack that meets safety, durability, and size requirements. Consider factors such as heat dissipation, protection against physical damage, and ease of installation.

BMS Selection: Choose a Battery Management System (BMS) suitable for LiFePO4 chemistry and compatible with the desired voltage and capacity of the battery pack. The BMS is essential for monitoring cell voltages, balancing cells, and providing overcharge/discharge protection.

Assembly: Assemble the battery pack according to the planned configuration and design. This typically involves spot welding or soldering cells together, connecting them in the desired series/parallel configuration, and integrating the BMS.

Testing: Perform comprehensive testing on the battery pack to ensure it meets performance and safety standards. This includes capacity testing, voltage measurements, temperature monitoring, and verifying proper BMS functionality.

Integration: Integrate the battery pack into the target application, whether it's an electric vehicle, renewable energy system, or another device. Ensure proper connections, cooling (if required), and safety precautions are implemented.

Quality Assurance: Conduct ongoing monitoring and quality assurance to ensure the long-term reliability and performance of the battery pack. This may include regular maintenance, monitoring cell balance, and replacing components as needed.

Regulatory Compliance: Ensure compliance with relevant regulations and standards for battery packs, such as UN38.3 for transportation and safety standards like UL or IEC.

Throughout this process, it's essential to prioritize safety and quality to prevent issues such as thermal runaway, overcharging, or short circuits, which can lead to safety hazards or premature failure of the battery pack. If you're not experienced in designing or assembling battery packs, it's advisable to seek assistance from professionals or companies specializing in battery technology.

lithium ion phosphate battery packlithium ion phosphate battery packlithium ion phosphate battery packlithium ion phosphate battery packlithium ion phosphate battery packlithium ion phosphate battery packlithium ion phosphate battery packlithium ion phosphate battery packlithium ion phosphate battery pack48v 300ah lifepo4 battery pack48v 300ah lifepo4 battery pack48v 300ah l8v 300ah lifepo4 battery pack48v 300ah lifepo4 battery pack48v 300ah lifepo4 battery pack48v 300ah lifepo4 battery pack48v 300ah lifepo4 battery pack48v 300ah lifepo4 battery pack48v 300ah lifepo4 battery pack48v 300ah lifepo4 battery pack48v 300ah lifepo4 battery pack

Home Solar SystemHome Solar SystemHome Solar SystemHome Solar SystemHome Solar SystemHome Solar SystemHome Solar SystemHome Solar SystemHome Solar SystemHome Solar SystemHome Solar SystemHome Solar SystemHome Solar SystemHome Solar SystemHome Solar SystemHome Solar SystemHome Solar SystemHome Solar SystemHome Solar SystemHome Solar SystemHome Solar System15KWH LiFePO4 battery pack15KWH LiFePO4 battery pack15KWH LiFePO4 battery pack15KWH LiFePO4 battery pack15KWH LiFePO4 battery pack15KWH LiFePO4 battery pack15KWH LiFePO4 battery pack15KWH LiFePO4 battery pack15KWH LiFePO4 battery pack15KWH LiFePO4 battery pack15KWH LiFePO4 battery pack15KWH LiFePO4 battery pack15KWH LiFePO4 battery pack15KWH LiFePO4 battery pack15KWH LiFePO4 battery pack15KWH LiFePO4 battery pack